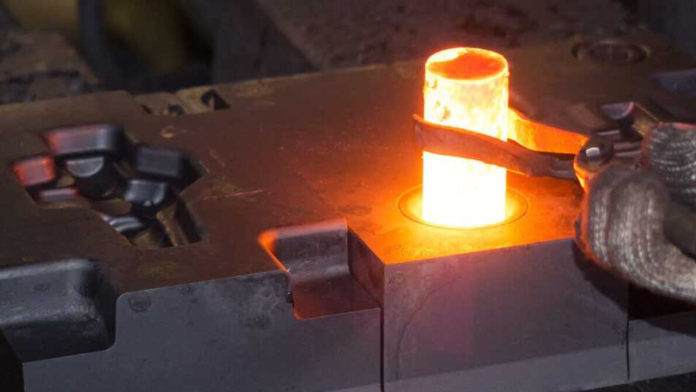

In the metalworking process known as “hot die forging,” a heated workpiece is formed between precisely machined dies while high pressure is applied. Forging allows for maintaining a temperature above the recrystallization point of the material, which increases its plasticity and facilitates complex shaping.

Creating intricate, vital components with exceptional mechanical qualities is a specialty of this process. The heated dies are crucial to shaping and preserving material integrity. With benefits like better material qualities, accurate shaping, and effective production of sturdy metal components, hot forging is widely used in manufacturing, aerospace, and automotive sectors.

Essential Factors for a Successful Hot Die Forging Process

A workpiece is heated to a high temperature and then shaped using a die in the metal-forming process known as hot die forging. Adherence to crucial considerations, meticulous planning, and attention to detail are necessary for successful hot die forging. A few essential elements for a successful hot die forging process are as follows:

Material Selection:

A critical step in the hot die forging process is selecting the appropriate material. The best materials, like titanium alloys, stainless steel, and alloy steels, can be forgeable at high temperatures. To withstand the harsh conditions during forging, the chosen material should have advantages like high strength, low ductility, and excellent thermal conductivity.

Temperature Control:

The success of hot die forging depends on maintaining accurate temperature control. A precise temperature must be reached for the metal to guarantee maximum plasticity and lower the force needed for deformation. Precise temperature control aids in avoiding problems such as underreacting, which results in incomplete forging, or overheating, which can cause poor surface finish.

Die Design and Material:

Achieving the intended shape and quality of the forged part depends heavily on the die’s design. Die materials must be highly thermally conductive, wear-resistant, and durable to endure repeated cycles of heating and cooling. Draft angles, fillets, and radii are features used in proper die design that help to promote metal flow and reduce stress concentration.

Die Preheating:

The die must be preheated to guarantee a consistent temperature distribution and avoid thermal shocks during the forging process. Thermal shocks can harm the surface finish of the forged component and cause an early die failure. Die preheating helps to keep forging conditions constant and extends the tool’s lifespan.

Press Capacity and Forging Force:

Selecting the suitable press capacity and forging force is essential to getting the required deformation without overstressing the dies. During the forging process, the press must apply enough force while still being precise and in control. It is essential to balance the material’s force and flow properties to prevent flaws and guarantee uniform deformation.

Cooling Rate and Heat Treatment:

It is essential to control the cooling rate after forging to achieve the proper material properties. By applying the proper heat treatment techniques, such as quenching and tempering, the forged part’s mechanical properties, such as its strength, toughness, and hardness, can be enhanced. Carefully considering the cooling process lowers the likelihood of cracks and other defects and guarantees a consistent grain structure.

Inspection and Quality Control:

A robust inspection and quality control system must be implemented to find and fix any flaws in the forged components. Non-destructive testing techniques like magnetic particle inspection and ultrasonic testing help the integrity of the parts. To fulfill the requirements, surface finish and dimensional accuracy should also be regularly checked.

Process Monitoring and Optimization:

Real-time adjustments and optimization are made possible by continuously monitoring the hot die forging process. Quick corrective action is made possible by the identification of deviations from the desired parameters through the use of sensors and feedback systems. Process optimization pertains to adjusting variables like temperature, forging speed, and die lubrication to maximize productivity and minimize expenses.

Last Summary

Manufacturers can create superior forged components with better mechanical qualities and dimensional accuracy by carefully evaluating variables like material selection, temperature control, die design, and quality control. By considering these essential factors, you can guarantee the success of individual forging processes while enhancing the manufacturing operation’s overall efficiency and competitiveness.